SINCE 1995

Company established in 1995

Sold to more than 30 countries

WHO ARE WE ?

Runhang Machine

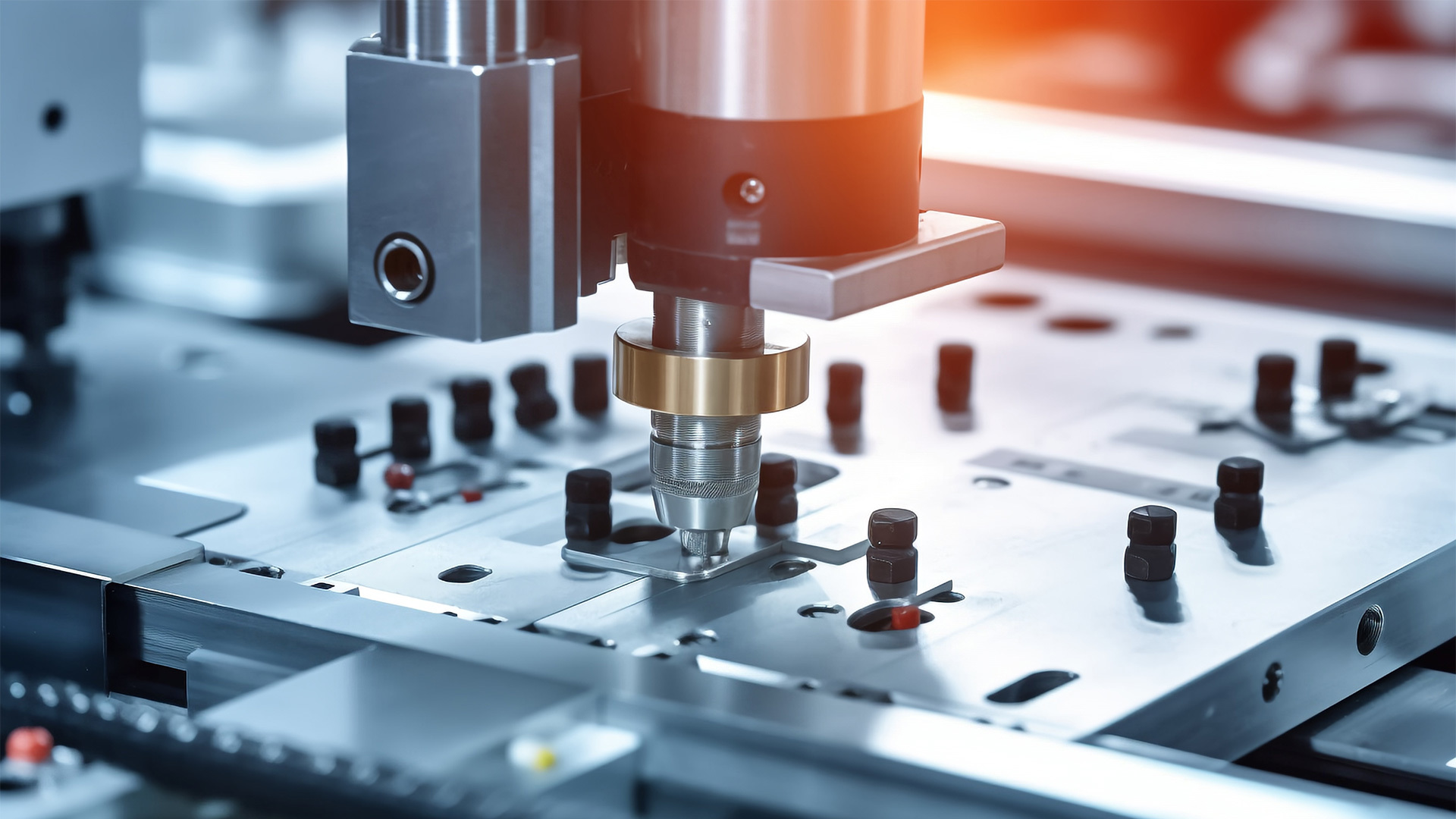

Yunnan Runhang Precision Machinery Co., Ltd. was established in 2016. The company is mainly a full-function CNC lathe with hard rail (sliding guide rail) CNC inclined guide rail, turn-milling compound machine and nano-scale high-precision CNC vertical compound grinder. The company adheres to the business philosophy of specialization, specialization and refinement, does a good job, does not make products unfamiliar to the company, and insists on serving the enterprise with "first-class products, the company does not do the supermarket business model, the company adheres to the quality control model that satisfies customers and makes salespeople confident (face-saving), and does not do the development model of" big but not strong, big but not refined "; the company insists on: The factory management model of" diligence, industry in follow ", aims at similar products in Europe and Japan, and does not use domestic or surrounding enterprises as competitors. Surpassing is the absolute principle.

After years of development, the company has become a self-contained enterprise, from product design, precision parts processing, assembly, and sales. Products are increasingly recognized at home and abroad. Welcome all colleagues and entrepreneurs with common values to guide the work of the company.

Product Center

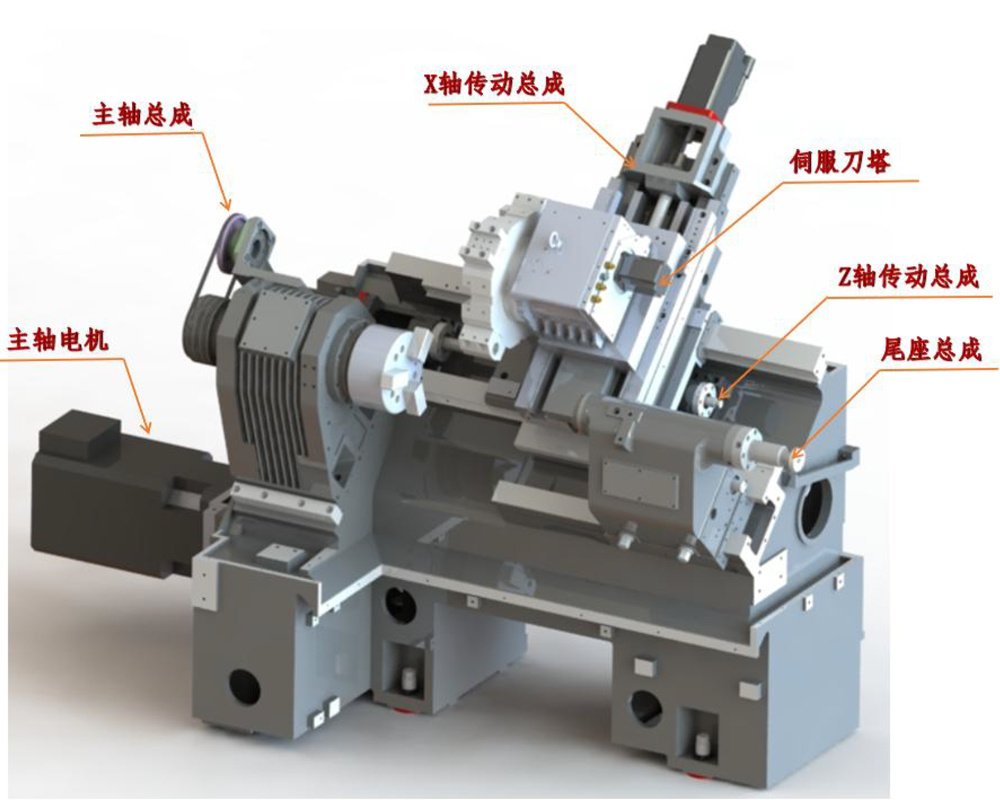

RH-20H-400 (hard rail) horizontal slant bed CNC lathe finishing machine

RH-20H-400 (hard rail) horizontal slant bed CNC lathe finishing machine

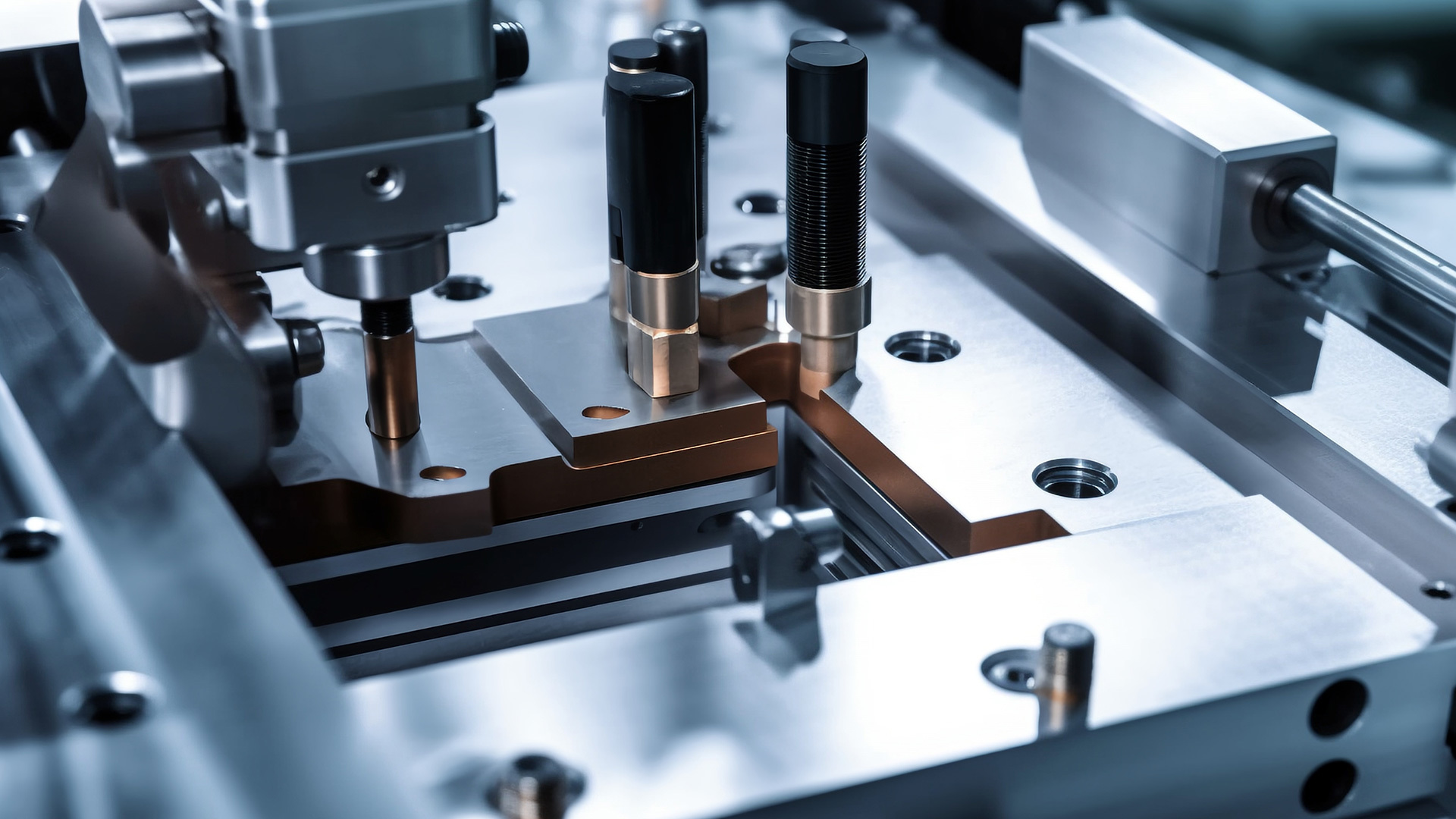

Both X and Z guide rails are hard rails; the main machine does not include: chuck, turret, motor, electrical components, electrical box, and peripheral sheet metal parts, which are assembled, inspected, and painted according to relevant international and domestic standards.

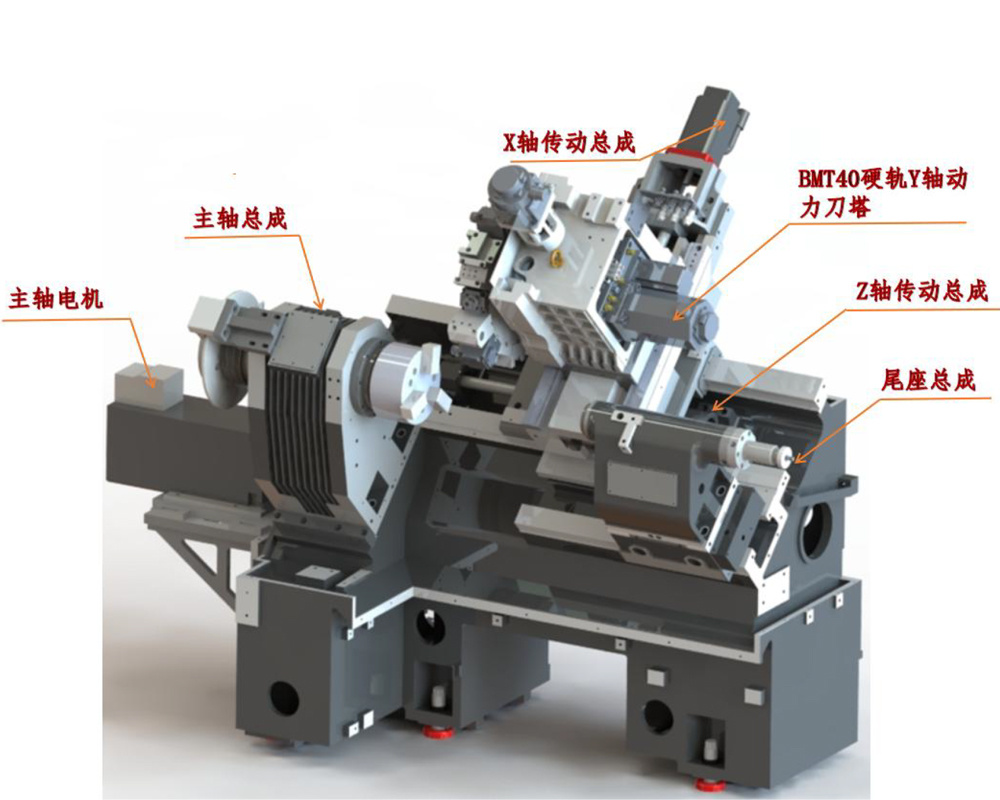

RH-20H-400M (hard rail) horizontal slant bed CNC turning center light machine

RH-20H-400M (hard rail) horizontal slant bed CNC turning center light machine

Special configuration: (This configuration can be customized according to customer requirements, with prices calculated separately): 1. Hydraulic chuck and high-speed rotary cylinder. (Germany ROHM / South Korea RYON / Taiwan Yichuan / Domestic Keput) installation completed. 2. Sheet metal (including internal and external protection). 3. Hydraulic station; (Taiwan Weisheng / Domestic Jiayong) installation completed, oil circuit distribution and installation. 4. Tool turret; Sanhe tool turret SHD16U-330, SHD20U-330. 5. Encoder bracket. (No encoder) 6. Brake assembly.

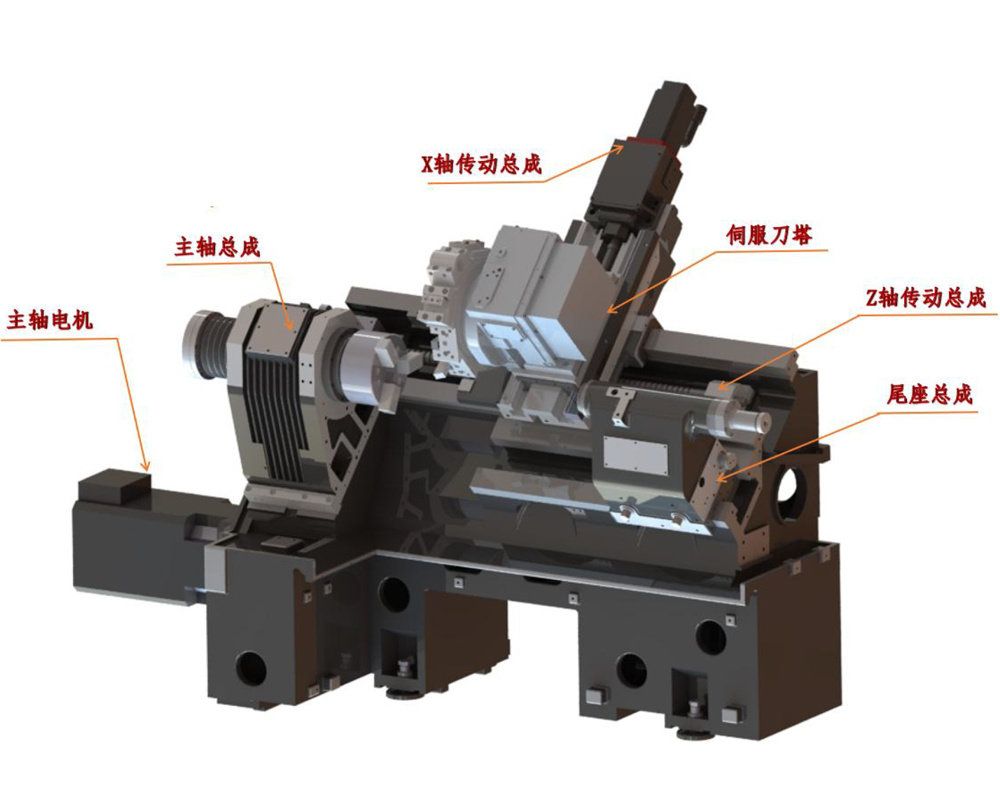

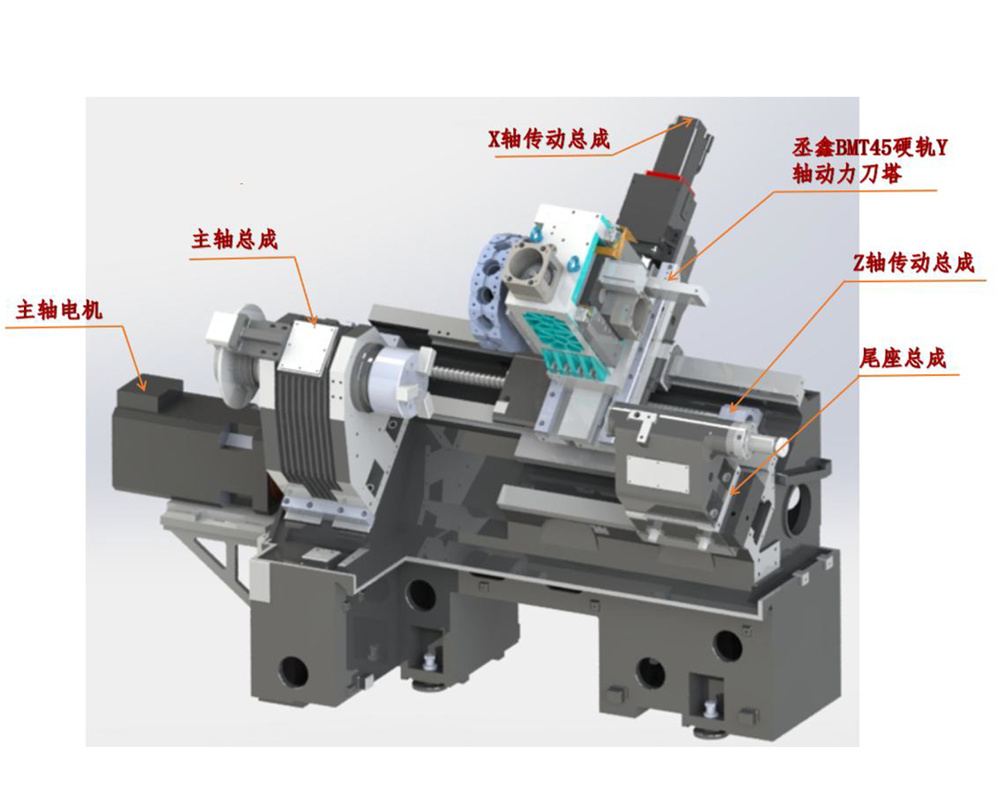

RH-20H-400MY Horizontal (Hard Rail) Slant Bed CNC Turning and Milling Composite Machine

RH-20H-400MY Horizontal (Hard Rail) Slant Bed CNC Turning and Milling Composite Machine

Both X and Z guide rails are hard rails; the main machine does not include turret, chuck, motor, electrical components, electrical box, and internal and external protective metal parts, and is assembled, inspected, and painted according to relevant international and domestic standards.

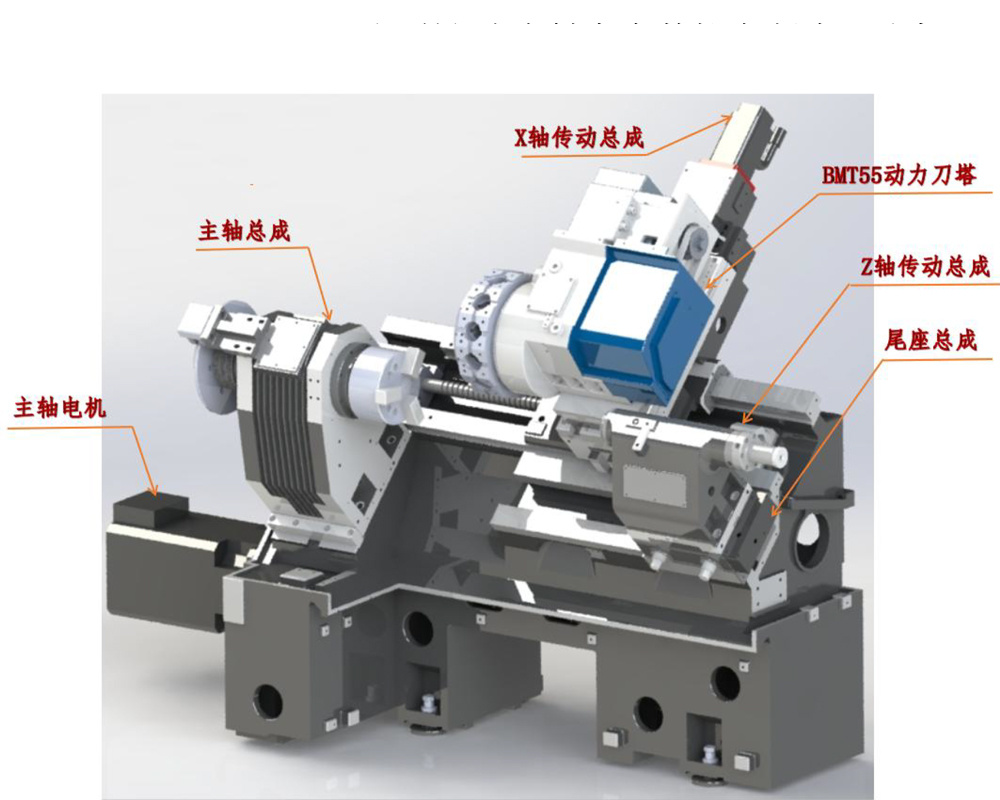

RH-20H-500 (hard rail) horizontal slant bed CNC lathe finishing machine

RH-20H-500 (hard rail) horizontal slant bed CNC lathe finishing machine

Both X and Z guide rails are hard rails; the main machine does not include: chuck, turret, motor, electrical components, electrical box, and peripheral sheet metal parts, which are assembled, inspected, and painted according to relevant international and domestic standards.

RH-20H-500M (hard rail) horizontal slant bed CNC turning center light machine

RH-20H-500M (hard rail) horizontal slant bed CNC turning center light machine

Hydraulic chuck and high-speed rotating cylinder. (Germany ROHM / South Korea RYON / Taiwan Yichuan / domestic KOPTE) Installation completed, and dynamic balance testing done.

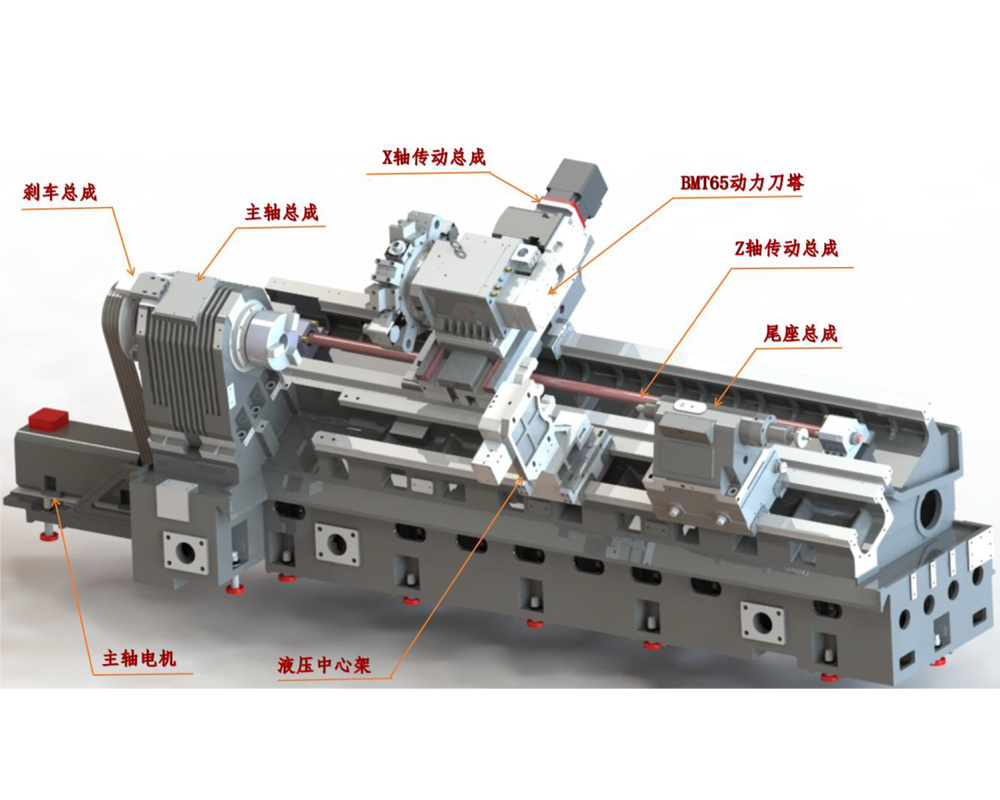

RH-20H-500MY (Hard Rail) Horizontal Slant Bed CNC Turning and Milling Composite Machine

RH-20H-500MY (Hard Rail) Horizontal Slant Bed CNC Turning and Milling Composite Machine

Main spindle assembly: The spindle is an NN structure assembled spindle, and the bearings use domestic CSC bearings (imported "SKF/NSK" bearings are optional);

RH-25H(A) (Hard Rail) Horizontal Slant Bed CNC Lathe Machine

RH-25H(A) (Hard Rail) Horizontal Slant Bed CNC Lathe Machine

Both the X and Z guide rails are hard rails; the main machine does not include the chuck, turret, center frame, motor, electrical components, electrical box, and internal and external protective metal parts, and is assembled, inspected, and painted according to relevant international and domestic standards.

RH-25H(A)-M (Hard Rail) Horizontal Slant Bed CNC Turning Center Light Machine

RH-25H(A)-M (Hard Rail) Horizontal Slant Bed CNC Turning Center Light Machine

Both the X and Z guide rails are hard rails; the main machine does not include the chuck, turret, center frame, motor, electrical components, electrical box, and internal and external protective metal parts, and is assembled, inspected, and painted according to relevant international and domestic standards.

产品中心

Products center

Why choose us?

Technology and process at home and abroad

The production of products are independent research and development manufacturing

Have a strong technical team

Have a technically proficient, experienced, pioneering and innovative technical team

Always adhere to the four principles

No brand, no complete machine, no exhibition, no sales department

advanced technology

Exquisite technology, strength, brand accessories. Let you rest assured!

Quality Assurance

Establish and implement quality management in strict accordance with the ISO9002 certification system

After-sales advantage

As always, we firmly carry out the competition core of "quality and high quality", improve the service with our heart, develop with our customers and make progress together.

20Year

Production experience

10000㎡

Production Workshop Area

96People

Production manufacturing workers

20000㎡

Floor Area

Provide solutions and high-quality technical support for enterprises.

Always adhere to the four principles: "do not do the brand, do not do the whole machine, do not participate in the exhibition, do not set up a sales department".

Your satisfaction is our goal.

Telephone:+8613700647358

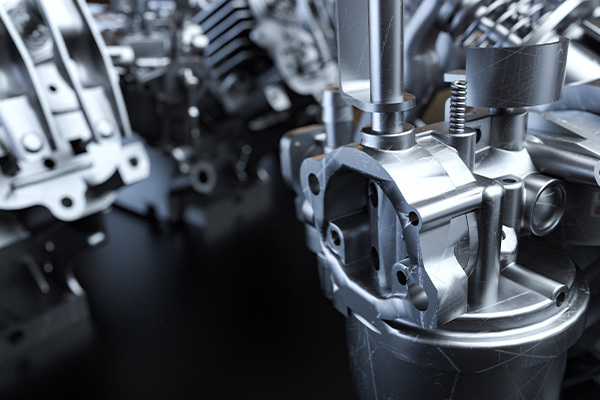

APPLICATION AREAS

Ship

Military Industry

Space

Automotive parts

NEWS INFORMATION

News

2024/08/29

2023/11/02

2023/07/04

Industry dynamics

Sincerely welcome the national seed industry colleagues and friends to visit the guidance