Information Details

RH-20H-400M (hard rail) horizontal slant bed CNC turning center light machine

Release time:

2023-10-20 11:33

CNC lathes are widely used.CNC machine toolsOne of them. It is mainly used forshaft partsor disc parts for machining inner and outer cylindrical surfaces, inner and outer conical surfaces with any cone angle, complex rotational inner and outer curved surfaces, and cylindrical and conical threads, as well as for grooving,drilling, reaming, boring, etc.

CNC machine tools automatically process the workpieces according to pre-programmed processing procedures. We write the processing technology route, process parameters, tool motion trajectory, displacement, cutting parameters, and auxiliary functions into a processing program sheet according to the instruction codes and program formats specified by the CNC machine tool, then record the contents of this program sheet on a control medium, and input it into the CNC device of the machine tool,CNC deviceto commandthe machine tool to processthe parts. In July 2023, the 25th Institute of China Aerospace Science and Industry Corporation successfully developed a high-precision optical automated centering CNC lathe that integrates optical detection, fine-tuning, and processing, and verified its technical level through engineering pilot applications, achieving a leading position in the country.

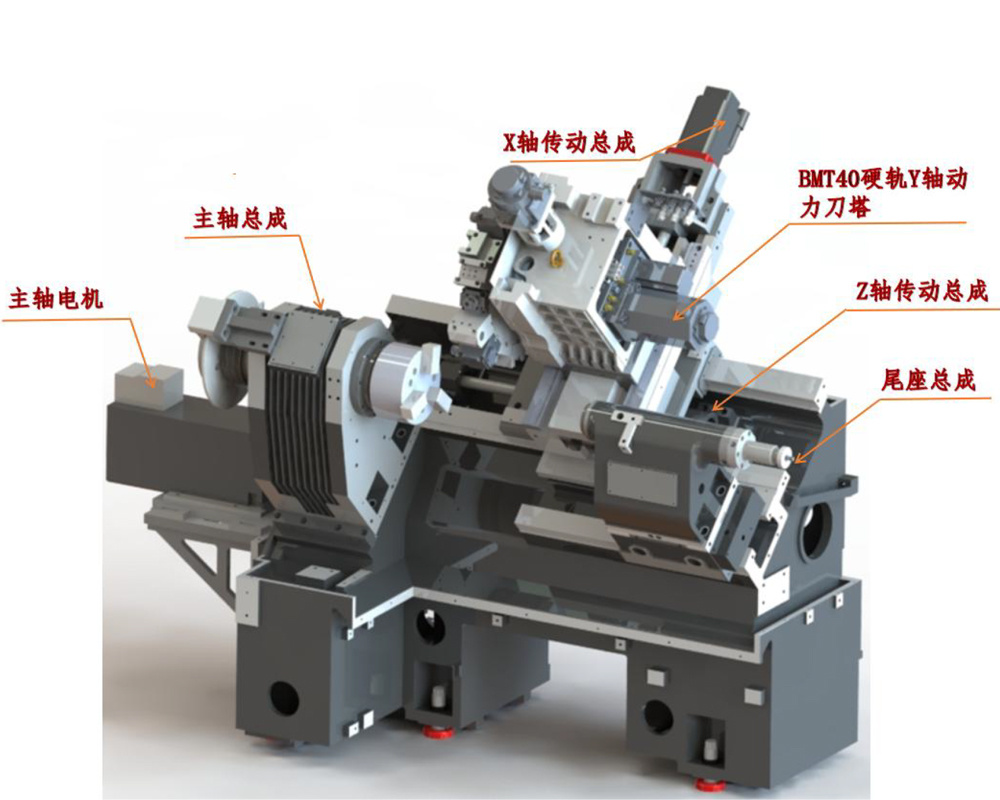

The CNC machine tool RH-20H-400M (hard rail) is a horizontal slant bed CNC turning center with high precision and stability.

This machine tool adopts a hard rail design, ensuring stability and precision during the machining process. Hard rails have high rigidity and stability, which helps improve the machine's vibration resistance during high-speed operation, thus ensuring precision and stability during machining.

In addition, this machine tool features a horizontal slant bed design, making workpiece clamping and processing more convenient. The horizontal design effectively reduces the machine's footprint and improves work efficiency. The slant bed design facilitates the discharge of cutting chips, ensuring stability and precision during the machining process.

The CNC machine tool RH-20H-400M is equipped with an advanced CNC system that can achieve multi-axis linkage control, suitable for complex machining tasks. The CNC system has high-precision position control and motion control functions, which can improve the machining precision and efficiency of the machine tool.

In addition, this machine tool is also equipped with a high-performance spindle, which has high rigidity and high load capacity. The spindle can achieve high-speed rotation, suitable for high-speed cutting and ** processing. At the same time, the spindle also has an automatic tool change function, allowing for quick replacement of various tools, improving the machining flexibility and efficiency of the machine tool.

In summary, the CNC machine tool RH-20H-400M (hard rail) is a horizontal slant bed CNC turning center with high precision and stability. It is suitable for various complex machining tasks, can improve machining precision and efficiency, and is one of the indispensable equipment in modern manufacturing.

CNC machine tools Runhang Precision Machinery

Previous Page

Next Page

Previous Page

Next Page

2024-08-29

Study of Germany's high-end manufacturing industry

2023-11-02

Germany European Machine Tool Exhibition

2023-11-02

2023 Innovation and Entrepreneurship Competition

2023-10-27